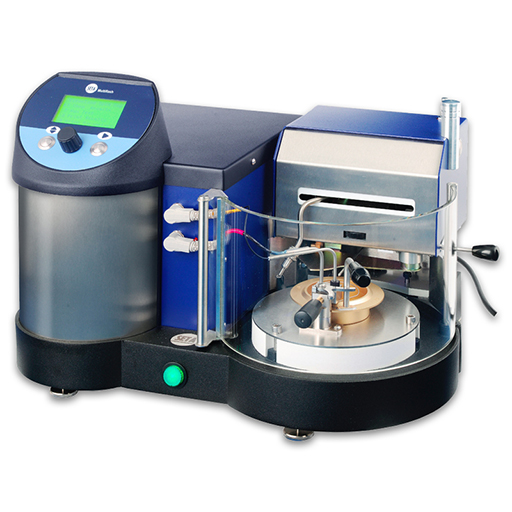

Seta Multiflash Cleveland Flash Point Module – 34300-2

The automatic Cleveland module conforms precisely to national and international Cleveland open cup flash point test methods. It comprises a sample cup, temperature probe, flash/fire detector, and a DIPS pod containing the sweeping mechanism with co-axial gas/electric ignitor.

The Cleveland module must be used with the Multiflash Automatic Flash Point – Universal Base Unit (34000-0). The base unit recognizes that the Cleveland module is connected and instantaneously sets up standard test parameters and calibration data.

Methods: ASTM D92, IP 36, BS DIN EN ISO 2592

Features

- Fully self-contained flash/fire point test module

- Ambient to 400 °C

- Gas or electric ignition

- Automatic heating control, flash and fire detection

- Automatic test results & end of test audible warning

- Automatic snuffer

- Automatic barometric correction

The flashpoint test area consists of a removable sample cup in a thermal insulation ring, and a probe block for mounting the flash/fire detector and sample temperature probe. The sample cup is heated by the hotplate within the Multiflash Automatic Flash Point - Universal Base Unit (34000-0).

The DIPS pod contains the ignitor sweeping mechanism with a coaxial gas jet/electric hot wire ignitor and a snuffer that extinguishes any flames in the sample cup at the end of the test.

The sample temperature probe is a class A PRT, and flash/fire detection is by an ionization ring.

Safety features include an initial sweep to check that the sample is below its flashpoint at the start of the test and a PRT check to ensure that the correct probe is connected and is immersed in the sample. When in search mode, the software limits the maximum temperature to 50 °C above "expected flash". The snuffer automatically deploys at the end of the test or if the independent fire detection probe (mounted over the test area) detects a flame. The hotplate in the Multiflash Automatic Flash Point - Universal Base Unit (34000-0) is equipped with a cut-out to protect against over-temperature.

The optional Cooling Boost Accessory (34008-0) allows the test area to be rapidly cooled in between tests by a blast of compressed air.

Supplied with;

DIPS Pod

Test Area

Ignitor

Ionization ring flash detector

Fire detector

Sample PRT

Sweep arm setup tools

Interconnection cables

Instruction manuals

Specifications

| TEMPERATURE RANGE | Ambient to 400 °C |

|---|---|

| BATH | N/A |

| HEATING | Hotplate |

| POST TEST COOLING | Fan assisted or Forced Air (Requires 34008-0 Cooling Boost Module option) |

| POST TEST COOL-DOWN TIME (90°C TO 50°C) | 9 minutes (Fan) 6 minutes (Forced Air) |

| IGNITOR | Quick-fit coaxial gas jet / electric hot wire, user-selectable (Electric hot wire pilot light for a gas jet) |

| TEMPERATURE PROBE | Class A Platinum Resistance Thermometer, °C or °F |

| FLASH / FIRE DETECTION | Ionization Ring |

| GAS SUPPLY (GAS JET IGNITOR) | Laboratory gas, 3 kPa (0.44 psi) maximum pressure |

| AIR SUPPLY (FORCED AIR COOLING | Dry compressed air, 670 kPa (100 psi) maximum pressure |

| VOLTAGE | 110/120 V or 220/240 V, 50/60 Hz, (switchable) |

| POWER | 1 kW |

| SIZE (HXWXD) | 330 x 470 x 420 mm |

| WEIGHT | 12 kg |

| CCCN CODE | Tariff 90268020 |

Accessories

Draught Screen – Multiflash (Cleveland) - 34010-0

RS232 Cable (to connect instrument to PC) - 34003-0

Cooling Module - 34008-0

Hussami Kit (Cleveland) - 34301-0

Data Printer - 81002-3

Co-axial Ignitor (Multiflash PMCC, Cleveland) - 34100-004

Insulating Collets (pack of 2) - 34300-014

Ionization Ring (Multiflash Cleveland) - 34300-201

Cleveland Standard 80 ml (3 pack) - 99882-0

FLASHCHECK (pack of 3 x 80 ml) - 99880-0