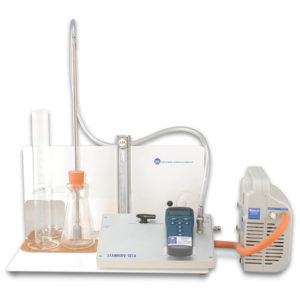

SetaFoam Dual Twin Foam Test Baths – 14020-8

These pair of highly transparent water baths are for detecting undesirable foaming characteristics in lubricating oils, which could cause inadequate lubrication, overflow, and cavitation.

The instrument comprises a high temperature (normally 93.5 °C) and a low temperature (normally 24 °C) bath, each with the capacity to hold four 1000 ml graduated glass cylinders.

Each bath assembly comprises an inner glass bath contained in a polycarbonate safety vessel and a top-mounted thermostir unit.

The bath has integral back-lighting with an opaque reflector which aids sample visibility and foam measurements. In addition, the low-temperature bath has a cooling coil for use when the laboratory ambient temperature exceeds the required bath temperature, and two air-normalizing coils to cool the air emerging from the high-temperature bath test cylinders prior to passing to external volume meters.

Methods: ASTM D892, IP 146, ISO 6247

Features

- Up to two simultaneous tests per bath

- Two pre-heating stations per bath

- Two integral normalising coils

- Local verification of the stones possible using the verification kit

The baths incorporate the Thermostir (15160-0) unit, which provides precision temperature control to within ±0.5 °C across a temperature range of ambient to 100 °C. It has an easy-to-use rotary dial and two function keys for quick temperature setting and menu navigation. The Thermostir is protected against overheating by an independent over-temperature cut-out which is user adjustable via the over-temperature dial.

Easy-to-remove stoppers ensure airtight seals and central location of the diffusers. All air connections are via quick-release connectors, and the diffuser tubes can be used with either Mott diffusers or Norton Stones.

Notes:

A DigiFlow Mass Flowmeter (14012-0) or Dual Glass Flowmeter (14011-2) is required per cylinder for testing. These are supplied separately and should be selected when ordering.

Stanhope-Seta recommends the use of the Pump and Accessory Kit (14019-2), supplied complete with a pressure relief valve and regulator. A Drying Tower (14015-2) is also available as an accessory. A clip to attach the drying tower can be mounted on the side of the flowmeter mounting bracket.

Supplied with:

Four graduated 1000 ml cylinders and stoppers

Interconnection tubing and junctions

Mains leads

Instruction manual

| OUTER | Polycarbonate |

|---|---|

| INNER | 28 liter, borosilicate glass |

| NO OF BATHS | 2 |

| NO OF CYLINDERS PER BATH | 4 (2 per bath supplied) |

| CYLINDERS | 1000 ml, borosilicate glass, graduated |

| DIFFUSER | Mott or Norton Stone |

| FLOWMETERS | 2 per bath, 94 ±5 ml/min |

| CONTROL UNITS | Thermostir, 1 per bath |

| TEMPERATURE RANGE | Ambient to 100 °C ±0.5 °C |

| SUPPLY VOLTAGE | 110/120 V, 60 Hz or 220/240 V, 50/60 Hz |

| POWER | 3kW |

| SIZE (HXWXD) | 70 x 48 x 40 cm |

| WEIGHT | 50 kg |

| CCCN CODE | Tariff 90268020 |