Refractometry or Refractive Index Measurement uses refractive index to characterize liquid or solid samples for concentration or purity determination. Every material or substance with which light interacts has a refractive index also referred to as refraction index or index

of refraction.

Refractive index is equal to the velocity of light of a given wavelength in space divided by its velocity in a substance. The velocity of light in a medium varies depending on the properties of the medium. In electromagnetic waves, the speed is dependent on the optical density of the medium where optical density is the tendency of the atoms in a material to restore the absorbed electromagnetic energy. The more optically dense a material is, the slower the speed of light. The refractive index is an indicator of the optical density of a medium.

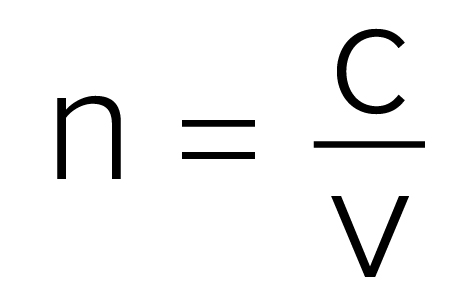

A refractive index is a number that indicates the number of times slower than a light wave would be in the material than it is in a vacuum. The refractive index (RI, represented by its symbol n),

is the velocity of light in a vacuum divided by the velocity of light in

a medium:

Where,

n is the refractive index

c is the velocity of light in a vacuum (3 × 108 m/s)

v is the velocity of light in a substance

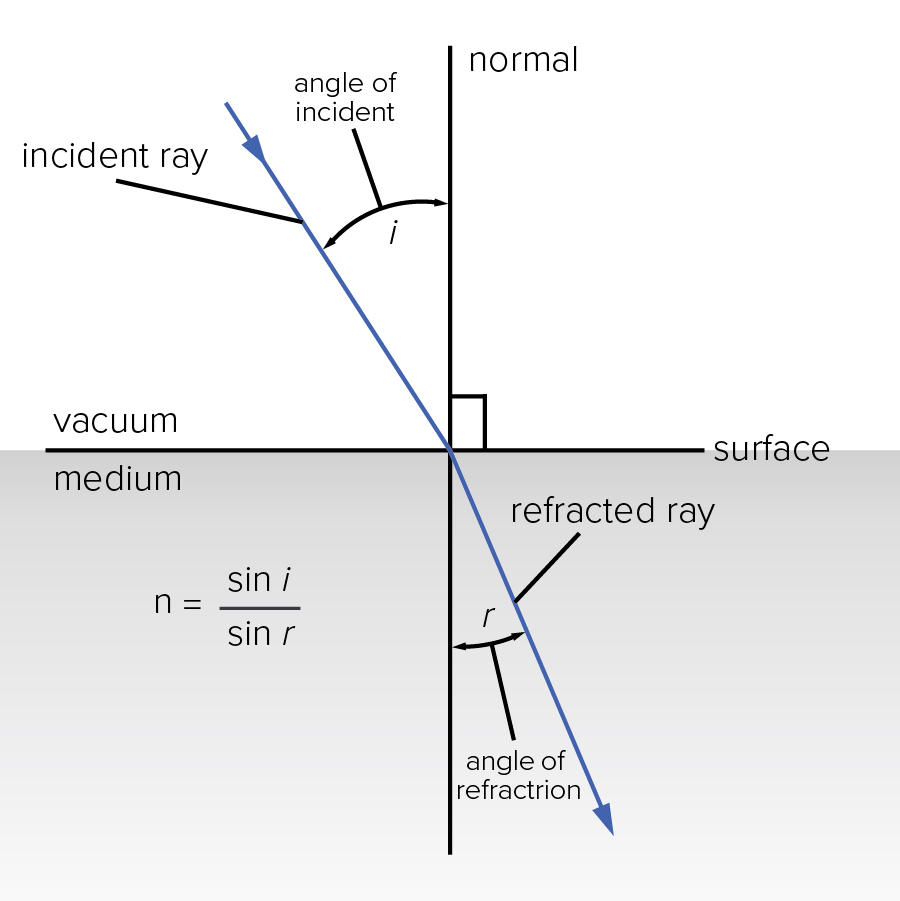

Refractive index is a measure of the bending of a ray of light when passing from one medium into another. With i being the angle of incidence of a ray in vacuum (the angle between the incoming ray and the perpendicular to the surface (normal) of a medium and r being the angle of refraction (angle between the ray in the medium and the normal), the refractive index n is defined as the ratio of the sine of the angle of incidence to the sine of the angle of refraction:

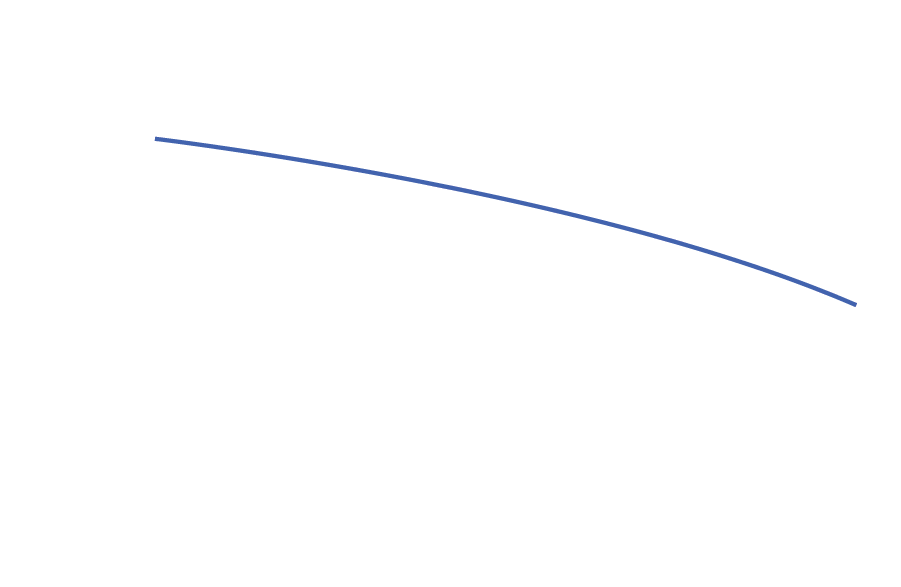

Refractive index is temperature-dependent. The higher the temperature of a medium, the higher the speed of light in the medium and the lower its refractive index as shown in the graph on the right. The speed of light depends as well on its wavelength. The shorter the wavelength of the light, the higher its speed. This frequency dependency is known as dispersion. Thus refractive index is always stated together with the temperature of the medium and the wavelength of light used for the measurement. Refractive index is normally measured at a temperature of 20°C using light with a wavelength of the yellow line of sodium (D-line, 589.29 nm) and is therefore expressed as nD20.

How a Schmidt+Haensch Digital Refractometer Works

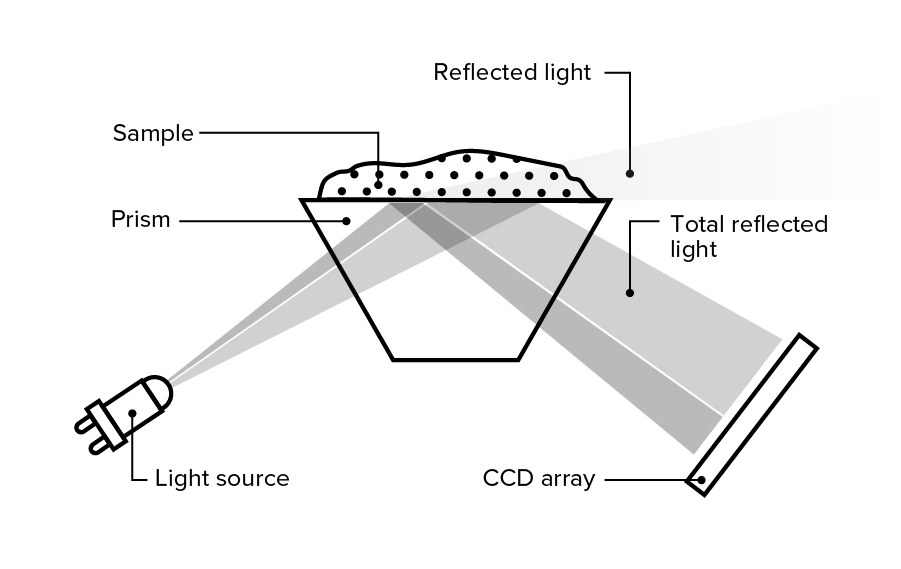

A modulated, high-intensity LED light source specifically designed to provide light energy at precisely 589.3 nm, the sodium D-line, the most common reference wavelength for refractive index measurements, focuses the light energy on the measuring surface of a prism. Most commonly a sapphire or YAG prism. In the absence of a fluid sample on the measuring surface, the total light energy is reflected internally toward a linear CCD array. With a fluid sample on the measuring surface, some of the light energy from the LED is predictably lost into the test fluid. Past the critical angle, all light energy is reflected internally from the measuring surface where a shadow line is projected on a high-definition CCD array.

Which Refractometer Is Right For You?

Determining which refractometer is right for you will depend on your need for precision, temperature control, your measuring range, sample throughput and location, and modularity. Following are the specifications for our line of Schmidt+Haensch refractometers and inline process refractometers.

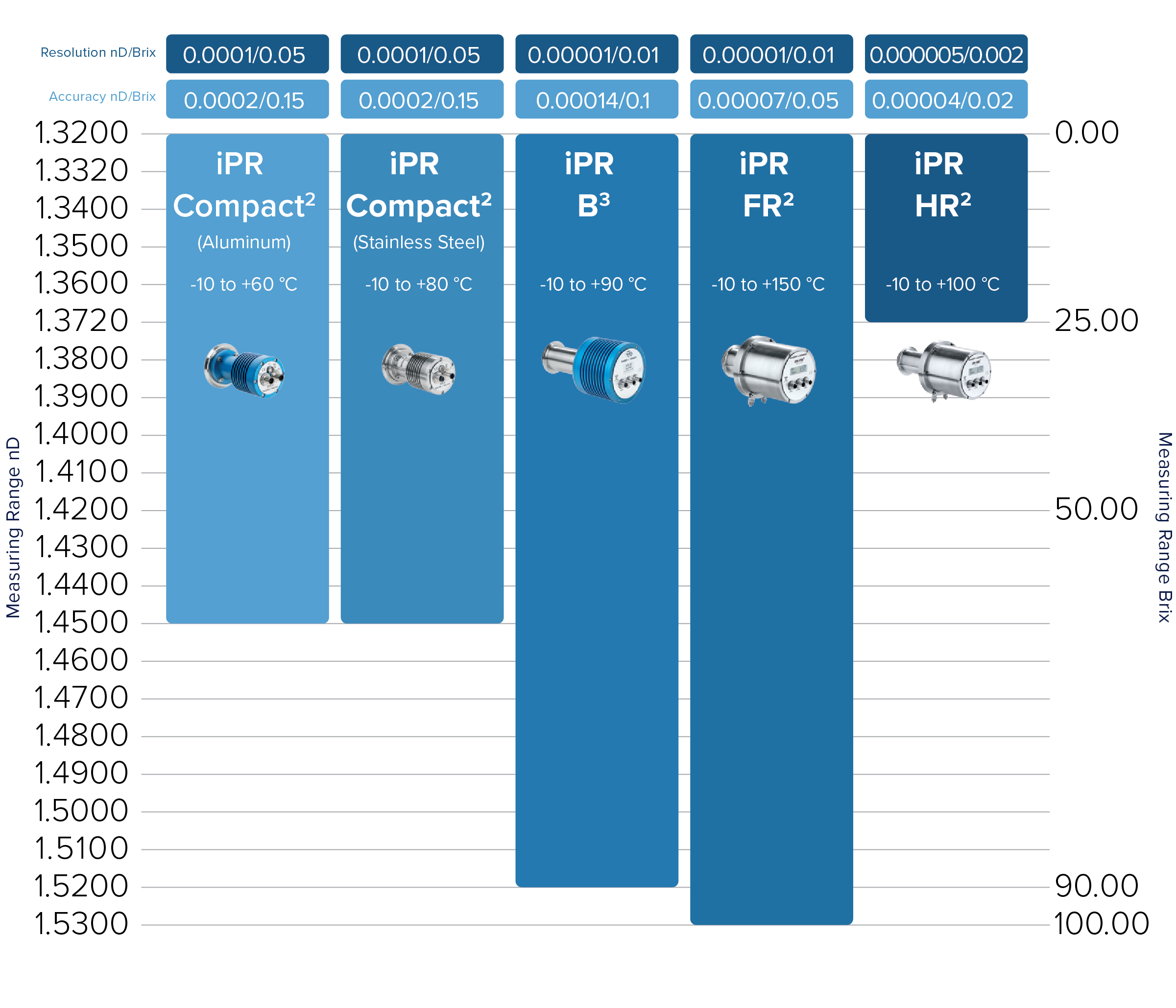

Inline Process Refractometers

Inline Process Refractometers measure the refractive index continuously and in real-time, thus determining the concentration of liquids or the mixing ratios of binary or quasi-binary mass ratios.

The measurement is independent of turbidity, color, absorption, and viscosity, which ensures maximum precision and better process control.

Applications for iPR Refractometers:

- Concentration monitoring

- Product interface detection

- Quality Control (Deviation from the target value)

- Crystallization monitoring

- Dosage control

Refractometer Model Comparrison

|  |  |  |  |  |

|

| VariRef A | VariRef B | VariRef C | ATR-L | ATR-P Touch | ATR-BR | |

| Refraction Method | Critical Angle | Critical Angle | Critical Angle | Critical Angle/Dispersion | Critical Angle | Critical Angle |

| Measuring Range | 1.32000 – 1.58000 RI / 100 °Brix | 1.32000 – 1.70000 RI / 100 °Brix (VariRef B1) 1.29000 – 1.58000 RI / 100 °Brix (VariRef B2) | 1.29000 – 1.58000 RI / 100 °Brix (VariRef C) | 1,33200 – 1,70000 RI / 100 °Brix | 1,32000 – 1,54000 RI / 100 °Brix | 1,32000 – 1,54000 RI / 0 – 100 °Brix |

| Resolution | 0.000001 RI / 0.001 °Brix | 0.00001 RI / 0.01 °Brix | 0.00001 RI / 0.01 °Brix | 0,00001 RI / 0,01 °Brix | 0,00001 RI / 0,01 °Brix | 0,00001 RI / 0,01 °Brix |

| Precision | ± 0,00002 RI* / ± 0.02 °Brix* | ± 0,00002 RI* / ± 0.02 °Brix* | ± 0,0001 RI* / ± 0.05 °Brix* | ± 0.00004 RI* / ± 0.03 °Brix | ± 0,00002 RI / ± 0,02 °Brix | ± 0,00002 RI / ± 0,01 °Brix (measurement range 1,32 – 1,44) and ± 0,00003 RI / ± 0,01 °Brix (measurement range 1,44 – 1,54) |

| Repeatability | ± 0.000005 RI / ± 0.006 °Brix | ± 0.00002 RI / ± 0.02 °Brix | ± 0.0001 RI / ± 0.05 °Brix | ± 0.00004 RI* / ± 0.03 °Brix | ± 0,00001 RI / ± 0,01 °Brix | 0,00001 RI / 0,01 °Brix |

| Measurement Mode | Single sample or flow through measurement (with optional compartment door) | Single sample or flow through measurement (with optional compartment door) | Single sample or flow through measurement (with optional compartment door) | Single sample | Single sample or flow-through measurement | Single sample |

| Ambient Temperature | + 10 °C to + 40 °C | + 10 °C to + 40 °C | + 10 °C to + 40 °C | 15 °C – 40 °C | +10 – +40 °C | +10 – +40 °C |

| Temperature Measurement | Pt 1000 sensor | Pt 1000 sensor | Pt 1000 sensor | NTC sensor for measurement of sample temperature placed inside the prism | NTC sensor for measurement of sample temperature placed inside the prism | NTC sensor for measurement of sample temperature placed inside the prism |

| Sample Temperature Control | Double isolated Peltier system | Double isolated Peltier system | Double isolated Peltier system | Double isolated Peltier system | By external water bath | No temperature control |

| Temperature Control Range | + 20 °C others upon request | + 5 °C to + 100 °C | + 5 °C to + 80 °C | 10 °C – 80 °C | +5 – +50 °C | No temperature control |

| Temperature Resolution | 0.01 °C | 0.01 °C | 0.01 °C | 0.01 °C | 0.01 °C | 0.01 °C |

| Temperature Precision | ± 0.03 °C* | ± 0.03 °C* | ± 0.03 °C* | ± 0.03 °C* | ± 0.03 °C* | ± 0.03 °C* |

| Temperature Reproducibility | ± 0.02 °C | ± 0.02 °C | ± 0.02 °C | |||

| Temperature Compensation Brix | 10 °C – 80 °C | +5 bis +50 °C | +5 – +50 °C | |||

| Prism | Sapphire | YAG | Sapphire | YAG | Sapphire | Sapphire |

| Light Source/Wavelength | LED, interference filter 589 nm | LED, interference filter 589 nm | LED, interference filter 589 nm | LED, 7 discrete wavelength fixed 400, 450, 490, 545, 589, 660, 700 nm (others available) | LED, interference filter 589 nm | LED, interference filter 589 nm |

| Display | None, or 7” Touchscreen, 800 x 480 Pixel | None, or 7” Touchscreen, 800 x 480 Pixel | None, or 7” Touchscreen, 800 x 480 Pixel | Back lit LCD, 16 x16 characters | 7″ touch screen, 800 x 480 Pixel, 16 Bit colors | Back lit LCD, 16 x16 characters |

|

| DHR 95 |

| DHR Standard Model Measuring scales: Sugar% (Bx) / Refractive Index (RI) Measuring range: 0 - 95 Bx / 1.33 - 1.54 RI Resolution: 0.1 Bx / 0.0001 RI Precision: ± 0.2 Bx / ± 0.0003 RI |

| DHR Honey Measuring scales: Sugar % (Bx) / Water in Honey (%) Measuring range: 0 - 95 Bx / 10 – 30% Resolution: 0.1 Bx / 0.1 % Precision: ± 0.2 Bx / ± 0.2% |

| DHR Wine Measuring scales: % Mass w/w (%)/Alcohol Probable (AP) Measuring range: 0 - 35 % / 0 – 22 AP Resolution: 0.1 % / 0.1 AP Precision: ± 0.2 % / ± 0.2 AP |

| DHR Saline Measuring scales: Sugar % (Bx) / Saline (NaCl) Measuring range: 0 - 54 Bx / 0 – 28 NaCl Resolution: 0.1 Bx / 0.1 NaCl Precision: ± 0.2 Bx / ± 0.2 NaCl |

| DHR Aqua Measuring scales: Seawater PPT (Part Per Thousand) / Seawater Specific Gravity (SG) Measuring range: 0 - 180 Part Per Thousand / 1.000 - 1.070 SG Resolution: 1 Part Per Thousand / 0.0005 SG Precision: ± 1 Part Per Thousand / ± 0.001 SG |

| DHR PG Measuring scales: Propylene Glycol % by volume (%) / Propylene Glycol °C Protection (°C) Measuring range: 0 - 60 % / 0 to - 50 °C Resolution: 0.1 % / 1 °C Precision: ± 0.4 % / ± 1 °C |

| DHR EG Measuring scales: Ethylene Glycol % by volume (%) / Ethylene Glycol °C Protection (°C) Measuring range: 0 - 60 % / 0 to - 50 °C Resolution: 0.1 % / 1 °C Precision: ± 0.4 % / ± 1 °C |

| DHR DEF Measuring scales: Sugar % (Bx) / For measuring AdBlue© Measuring range: 0 - 54 Bx / 0 – 40 Resolution: 0.1 Bx / 0.1 Precision: ± 0.2 Bx / ± 0.2 |