AFIDA SA6000-0

Advanced Fuel Ignition Delay Analyser

- Indicated Cetane Number by CVCC

- Range 35 – 85 ICN

- Highly automated with autosampler

- Reference Fuel Calibration

- No bias correction to engine values

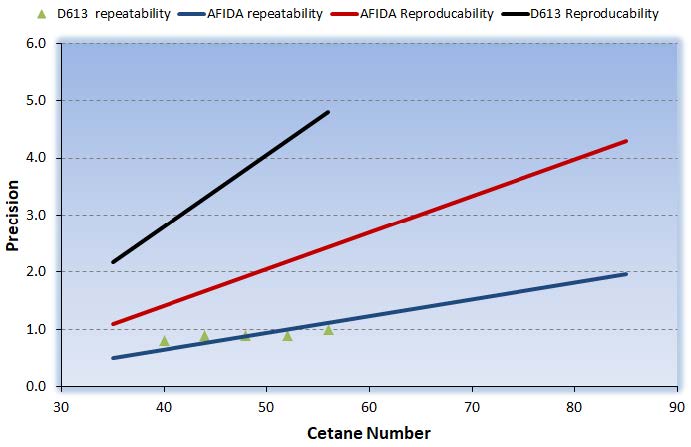

- Excellent precision to minimize giveaway

- Easy to use, suitable for 24/7 operation

- Load and go

Middle Distillates • Biodiesel • FAME • Jet A1 • HVO • XTL

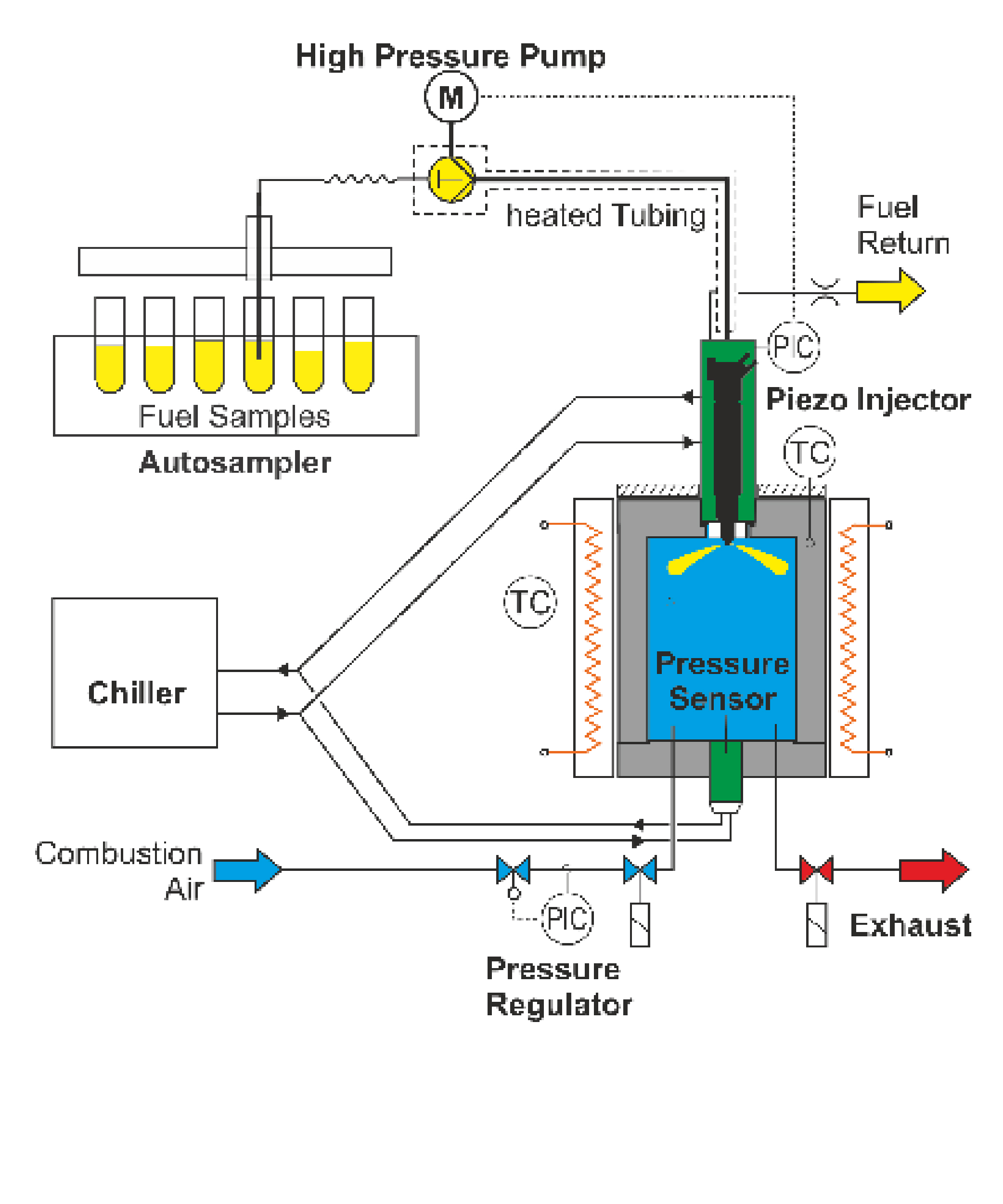

AFIDA is a revolutionary development providing a fully automated determination of the Indicated Cetane Number (ICN) of diesel and diesel related fuels.

The analyzer incorporates a unique and patented high-pressure injection system that generates fine fuel droplets similar to modern common rail injectors in most diesel engines.

A temperature controlled piezoelectric injector provides rapid switching and highly repeatable fuel metering, offering improved performance and consistency when compared with solenoid controlled injectors and pintle type nozzles.

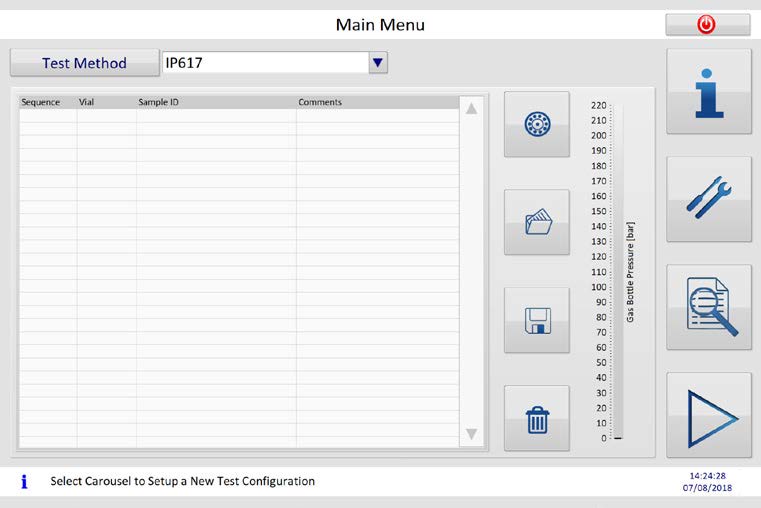

The analyzer provides very fast, efficient, and calibrated ICN determinations; tests are fully automated via an integral 36 position carousel and auto sampler.

Features

- Excellent correlation to ASTM D613, EN ISO 5165 & DIN 51773

- Integral 36 place carousel and auto sampler

- Calibrated with industry approved reference fuels

- Fully automated measurement

- Small sample volumes (approx 40 ml/analysis including flushing)

- Short analysis time of approximately 25 minutes per sample

- Precise and reproducible software controlled determination of ICN

- Advanced electronically controlled high pressure fuel injection system with piezoelectric injector

- Safe operation – integral safety monitoring functions

- Results saved to PC or for download

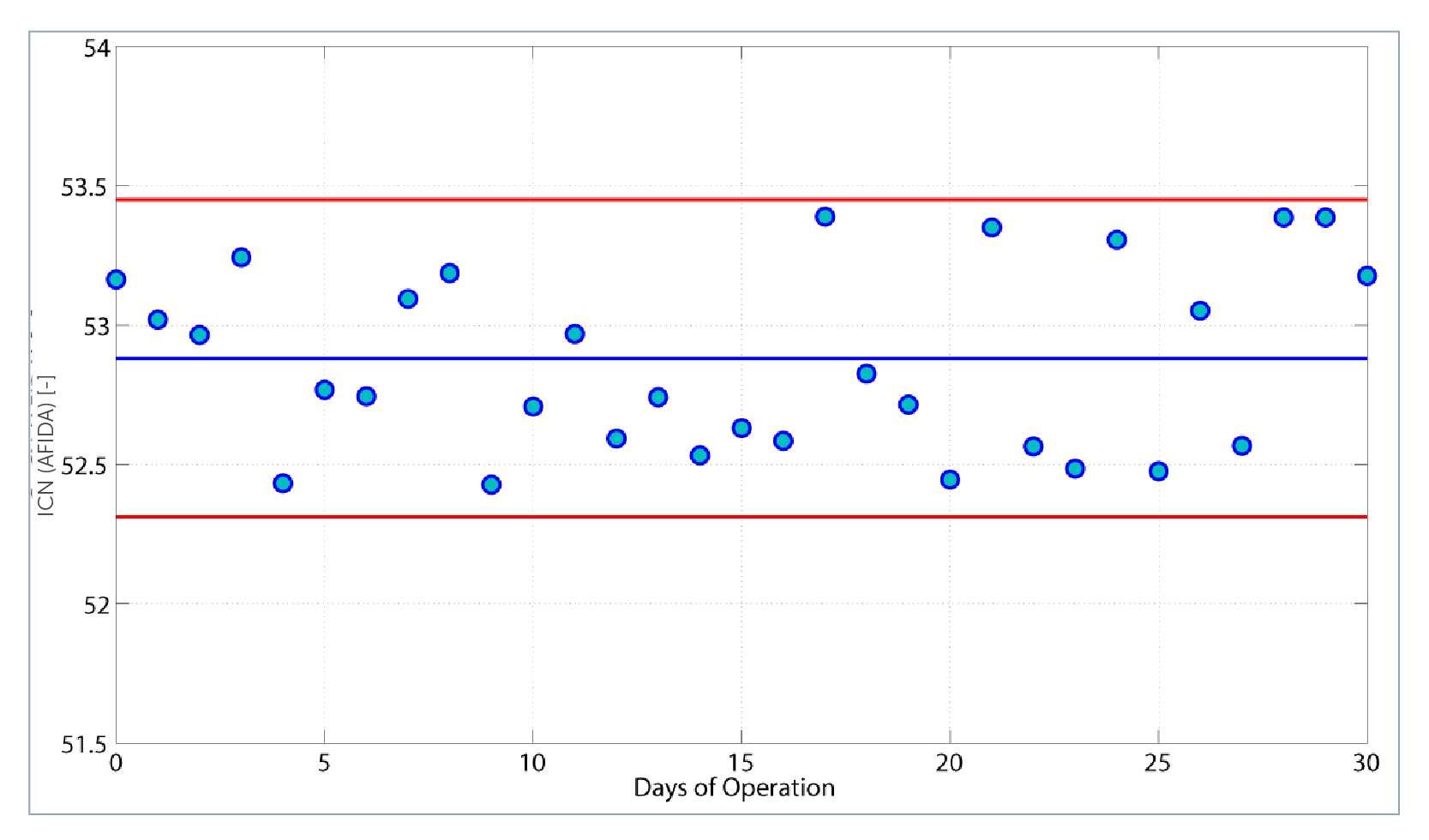

- Proven calibration stability – minimizing downtime (see figure 3)

- Uninterruptable power supply to maintain cooling in the event of power failure

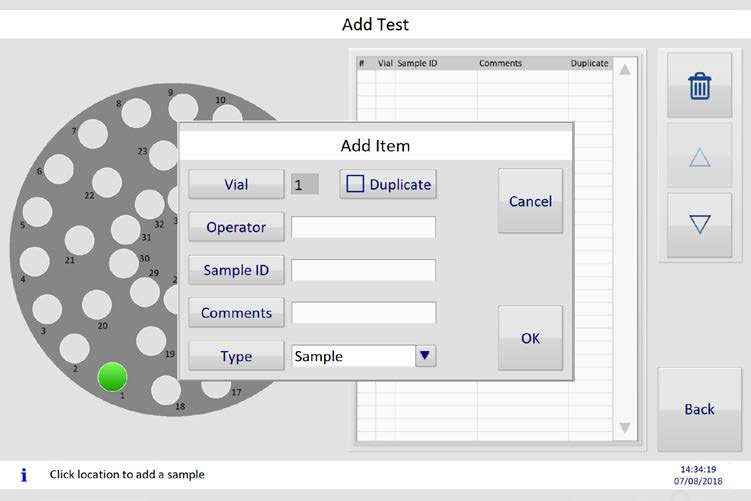

Sample Carousel

Piezo Electric Injector

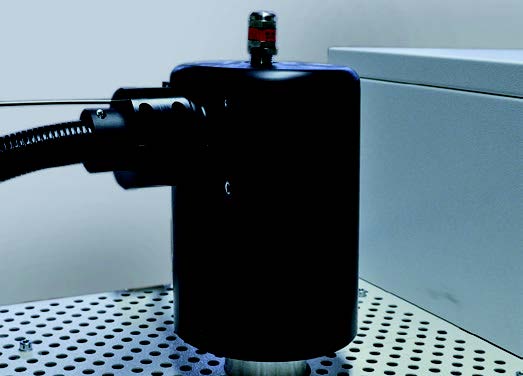

Figure 1: Calibration with 7 PRF blends covering measurement range CN 85 to CN 35

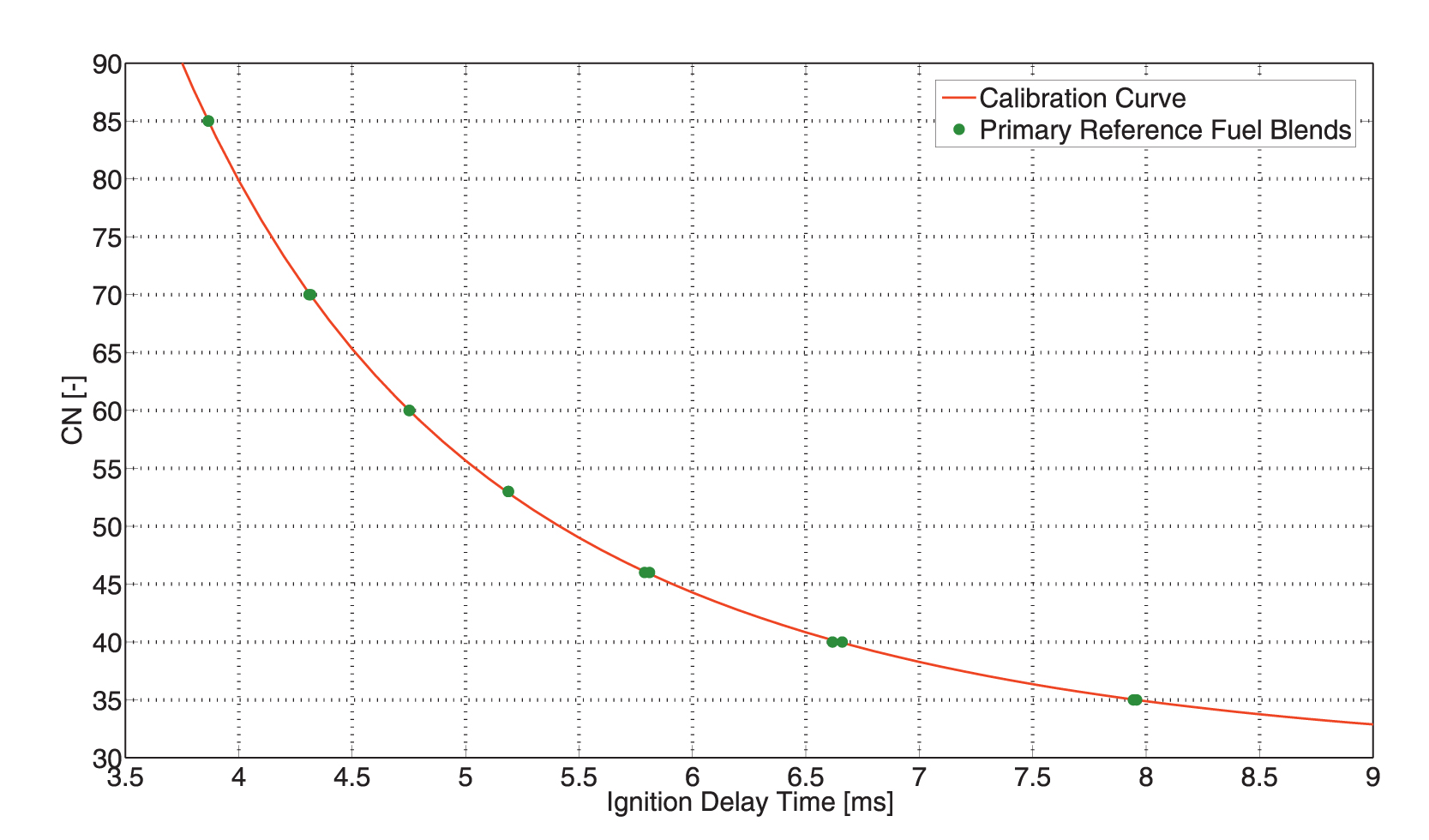

Figure 2: ICN correlation to Cetane Engine – R² = 0.9941

New Generation AFIDA Technology

Direct correlation to ASTM D613 (ISO 5165) engine tests

The traditional Cetane Engine methods establish an ignition delay period for the test fuel which is referenced to a primary reference fuel scale.

Existing Constant Volume Combustion Chamber (CVCC) technology provides a Derived Cetane Number (DCN) result based on a historical averaged correlation equation applied to the ignition delay of the fuel sample.

The new generation AFIDA technology is a significant step forward as it uses the original Primary Reference Fuels as specified in the Cetane Engine method to provide a calibrated Cetane Number measurement (see figure 1). This approach eliminates the need for temperature tuning and uses fixed test conditions.

Standardisation by CEN, ASTM and the Energy Institute

An EI inter-laboratory study was successfully completed with excellent precision and concluded no bias correction to ASTM D613 (cetane engine).

ASTM D8183, IP 617 and EN 17155 have now been included in EN 590; ASTM D975; ASTM D6751; ASTM D7467; ASTM 1655

Operating Sequence

- Prior to the analysis, each sample is filtered by the operator using a 0.45 μm filter.

- Software controlled autosampler selects the sample to be analysed

- System is cleaned automatically with the selected sample

- High pressure pump generates the injection pressure, while the heating tubes keep the fuel at a constant temperature

- Test sample is injected into the pressurized combustion chamber

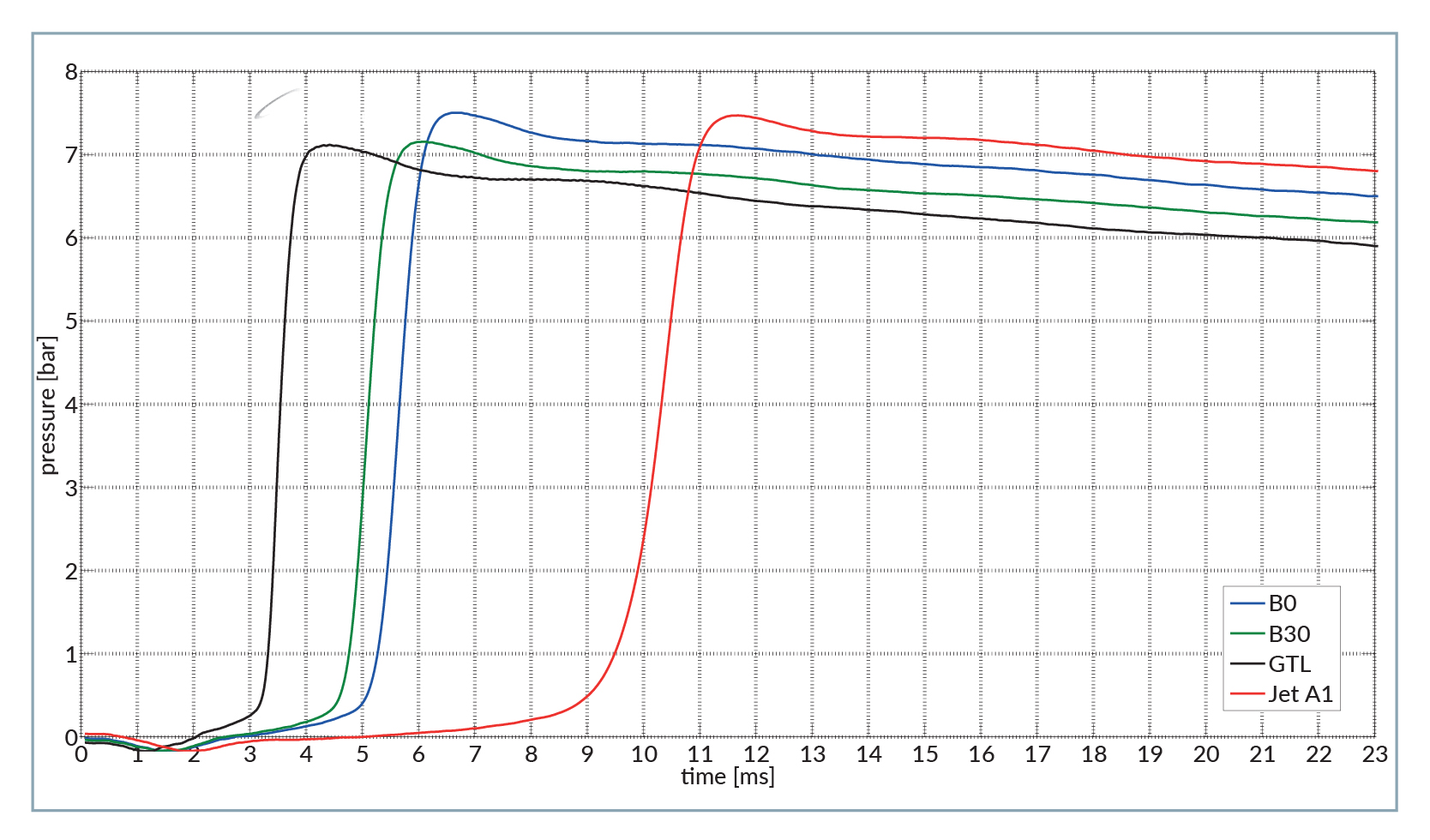

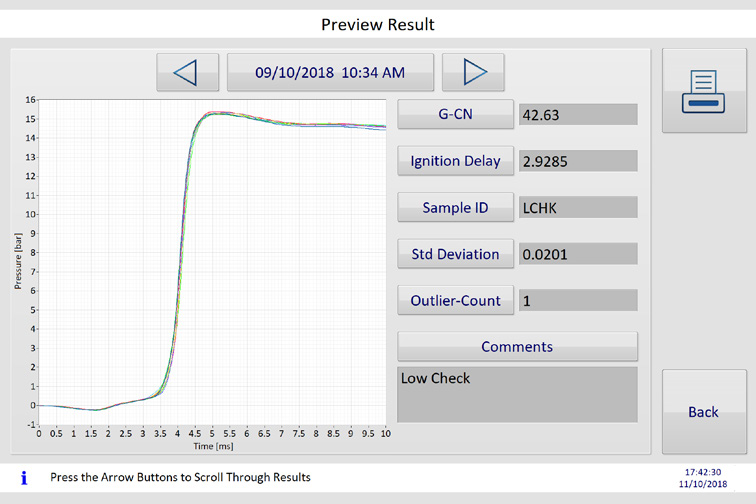

- Nebulized fuel ignites spontaneously and leads to a pressure increase; see figure 4

- The pressure variation curve is recorded at high resolution by a dynamic pressure sensor

- ICN is read directly from the calibration curve; see figure 1

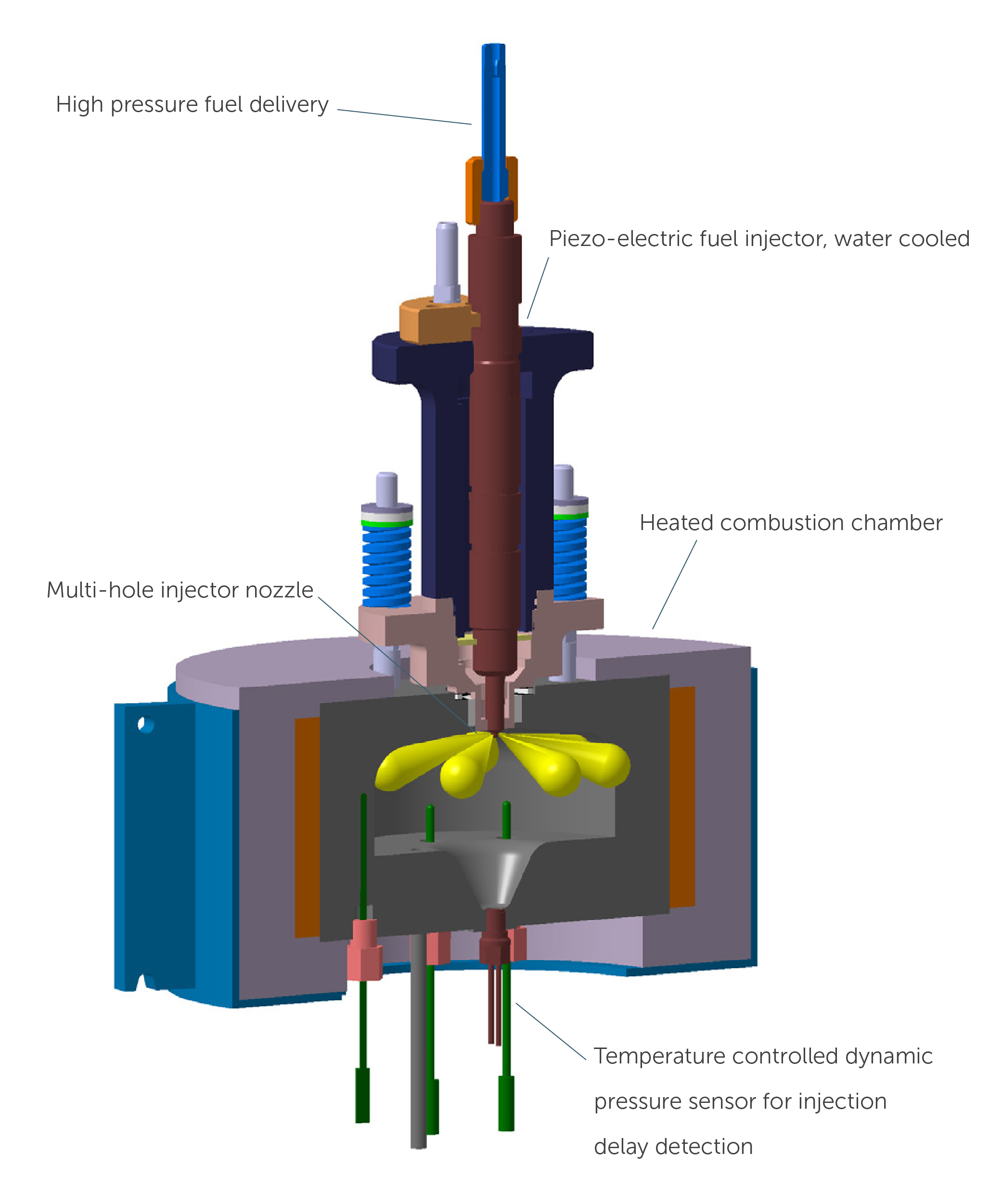

Features of the Chamber and Injector

- Fuel reservoir maintains high fuel pressure during injection

- Piezo-electric fuel injector as used in modern passenger cars’ diesel engines

- Water-cooled injector jacket maintains constant fuel temperature during operation

- Effective nozzle tip cooling to avoid fuel degradation due to high temperatures

- Real internal chamber temperature measurement

- Pressure transmitter connection free of acoustic oscillation

Figure 3: ICN variation during operation time

Figure 4: Pressure variation curves of four different fuels (B0, B30, GTL and Jet A1)

1. Place sample in carousel and select location

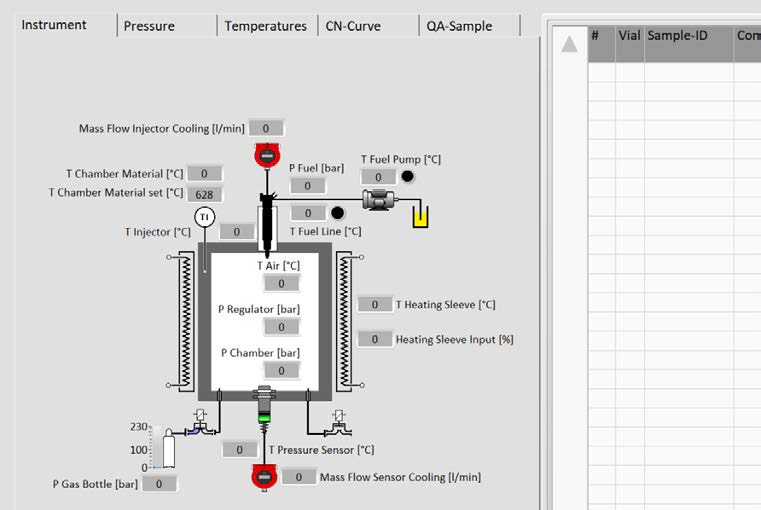

3. Monitor instrument status, pressure, temperatureor CN curve during test

2. Select test sequence and press go

4. View results

| AFIDA SA6000-0 Technical Specifications | |

|---|---|

| Operation | |

| Measurement Conditions | Chamber temperature: 580 °C Chamber pressure: 17.5 bar Injection pressure: 1000 bar Compressed air (20.9 ± 0.5 % O2) |

| Sample volume | approx. 40 ml for analysis and cleaning |

| Warm-up time | approx. 45 min |

| Analysis time | approx. 25 min per sample |

| Range for ICN | 35 - 85 in standard mode |

| Carousel capacity | 36 samples |

| Reporting | |

| Test parameters | All measurement values are stored in the data file |

| Reports | Detailed report of test results, date and time, operator name and calibration date |

| Safety | |

| External cooling | Backup power supply and liquid level sensor |

| Waste | Liquid level sensor |

| Various | Programmable Logic Controller (PLC) based |

| Requirements | |

| Operating Requirements | Ambient temperature: 10 °C to 35 °C (recommended 15 °C to 25 °C) Humidity: up to 80% non-condensing |

| Size (WxHxD) | 130 x 80 x 60 cm |

| Weight | Approx 100 kg (excluding platform) |

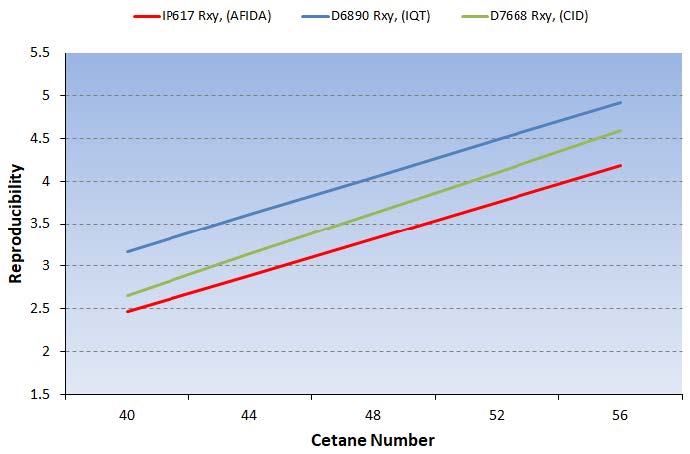

Best cross method Reproducibility to ASTM D613

Minimise giveaway – precision comparison

*Manufactured under licence from ASG Analytik-Service Gesellschaft mbH