What is Flash Point?

Flash point is defined as the lowest temperature of a liquid at which its vapors will form a combustible mixture with air. It is a convenient and reliable classification of the flammability of many substances, there are three main categories;

- Extremely flammable: Flash point below 0° C

- Highly flammable: Flash point below 21 °C

- Flammable: Flash point below 55 °C

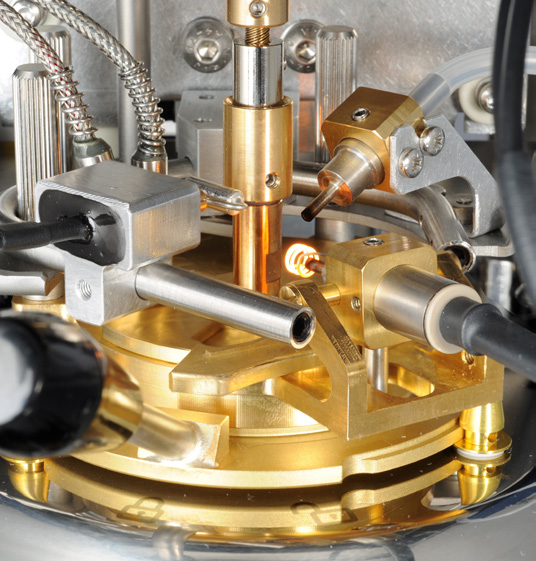

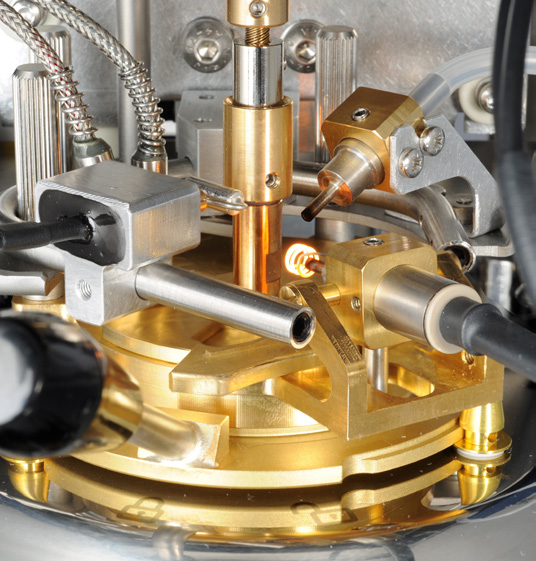

A sample of specified volume is introduced to the test cup which is maintained at the test temperature. After a specified time, a test flame is applied and the presence or absence of a flash observed.

Why Measure Flash Point?

Quality Control

Petroleum and chemical industries often use flash point testing to check for contamination or adulteration of a product. Multiple storage tanks may contain different products which can range in purity. These tanks may use common pipeline systems. The pipeline will be cleaned between product batches but there is a risk of contamination if they are not cleaned thoroughly. Flash point is used to determine whether contamination of a product has occurred.

Changes in flash point indicate that a sample may have been contaminated or adulterated, for example, petroleum spirit in engine oil will lower the flash point. Contamination of fuel oil, lubrication oil, and hydraulic oil by lighter hydrocarbons can lead to problems with the operation of expensive equipment on ships, at power plants in construction and mining machinery, etc.

Transportation and Storage Regulations – Hazard Classification

Flash point is used in shipping and safety regulations to define flammable and combustible materials and classify their hazard potential which has significant cost implications when transporting

or storing products.

Many industries use solvents in their products which are used to classify the flash point for the finished product. Some solvents are not highly flammable so establishing the exact flash point can help save money.

The Setaflash test method in these circumstances quickly provides an accurate flash point value to correctly classify the true hazard nature of a product and uses a small sample size.

Waste Disposal Regulations

Hazardous Waste Regulations require rapid hazard classification of a sample (liquids, used oils, and solids) before it can be disposed of.

Portable Setaflash small scale flash point testers are widely used in these circumstances for spot checks in the laboratory, on a production line, or outdoors. They reduce problems with waste handling and disposal because a test requires no more than 4 ml of sample.

Flash point is measured using either an open cup or closed cup flash point tester. Open cup tests are required in some specifications and regulations and are intended to mimic conditions in open spaces, whereas closed cup tests are closer to most situations, where space is restricted.

Closed Cup (CC)

Abel, Abel-Pensky, Pensky-Martens, Tag, Setaflash (CC)

Closed cup tests aim to simulate the situation of a liquid spill in a closed environment. If the liquid is at, or above, its flash point then a fire or explosion is a possibility when exposed to a potential ignition.

In closed cup tests, the sample is placed inside a sealed (closed) test cup and the ignition source is introduced to measure the temperature at which the sample ignites (‘flashes’), known as its flash point.

Open Cup (OC)

Cleveland, Setaflash (OC)

Open cup tests simulate the potential ignition of a liquid spillage in uncontained conditions, for example, a pool of liquid spilled on the floor. Fire point, combustibility, and sustained burning tests all use open cup instruments. Fire point may be considered as the lowest temperature of the liquid at which vapor combustion and burning commences when an ignition source is applied and continues to burn after the removal of the ignition source. Combustibility and sustained burning tests are usually carried out at a fixed temperature and test for continuous burning of the test specimen.

An open cup instrument will always give a higher flash point than a closed cup as the open cup allows free loss of vapors to the atmosphere above the instrument. Closed cup tests are usually specified due to improved precision.

Flash Point Test Methodology

Non-equilibrium – Abel, Pensky-Martens, Tag, Cleveland

The term non-equilibrium means the vapor is not in equilibrium with the liquid. Non-equilibrium flash point tests are when the liquid is heated at a steady rate of temperature increase while the ignition source is applied at regular intervals.

Advantages: It is well suited to automation, instrumentation is universally available and standardized for a wide range of products.

Disadvantages: Each time the flame is dipped, some of the valuable components may escape which can give artificially high flash points or spoil precision. The temperature of the liquid and vapor can significantly vary in the cup. Non-equilibrium tests require a large sample size of 50 to 80 ml per test.

Equilibrium – Setaflash

Traditional equilibrium flash point tests which use any cup in a water bath, ensure that the liquid and a vapor of the sample are in temperature equilibrium by adopting a complex procedure and a very slow heating rate.

The Setaflash small scale method overcomes the laborious processes associated with the other methods by utilizing a 2 ml or 4 ml sample which achieves ‘rapid equilibrium’ between the vapor and the liquid in a cup and gives a reliable flash point result in just one or two minutes.

Advantages: Improved precision compared to nonequilibrium methods. The Setaflash instrument range offers a low-cost, fast measurement for a flash/no flash result which is widely used by many industries.

Disadvantages: Traditional testers can involve a laborious process especially when larger amounts of a sample are needed to produce a representative sample. This type of instrumentation is not universally available.

The appropriate method for your sample is usually cited in a product specification or regulation, and in certain circumstances, a referee test method may be stated, this method should be the first choice. If alternative test methods are specified then the choice will be influenced by other factors such as sample size requirements, speed of testing, or precision.

When specifically testing for contaminants, certain test methods and procedures are more appropriate than others. In general, an equilibrium test method is recommended for testing samples that may contain traces of volatile contaminants.

Setaflash Small Scale

ASTM D1655; ASTM D3278; ASTM D3828; ASTM D7236;

ASTM D8174; ASTM E502

These methods cover petroleum products and biodiesel liquid fuels across the range of -30 to 300 °C using a small scale closed cup tester.

The procedures may be used to determine whether a product will or will not flash at a specified temperature (flash/no flash method A), or the flash point of a sample (method B). When used in conjunction with an electronic thermal flash detector, these methods are also suitable for flash point tests on biodiesels such as FAME.

Small scale testers are also used for shipping and safety regulations such as CLP to define flammable and combustible materials and classify them.

Pensky-Martens Closed Cup (PMCC)

ASTM D93; IP 34; ISO 2719

These test methods cover the determination of the flash point of petroleum products in the temperature range from 40 to 360 °C by a manual or automated PMCC apparatus. They are also used to determine the flash point of biodiesel in the temperature range of 60 to 190 °C by automated PMCC apparatus.

Tag

ASTM D56; ASTM D3934; ASTM D3941;

ASTM E502; IP 491; IP 492; ISO 1516; ISO 1523

These test methods cover the determination of the flash point by tag manual and automated closed testers, of liquids with a viscosity below 5.5 mm2/s (cSt) at 40 °C, or below 9.5 mm2/s (cSt) at 25 °C, and a flash point below 93 °C.

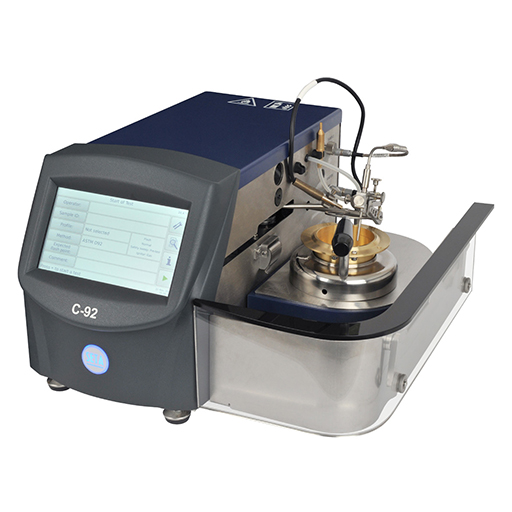

Cleveland

ASTM D92; ASTM D8254; IP 36; ISO 2592; DIN 51 376; NF T60-118; JIS K 2265-4; AASHTO T48

These test methods describe the determination of the flash point and fire point of petroleum products by a manual Cleveland open cup apparatus or an automated Cleveland open cup apparatus. It is applicable to all petroleum products with flash points above 79 °C and below 400 °C except fuel oils.

Abel

IP 170; IP 491; IP 492; ISO 5123; ISO 1376

These test methods describe the determination of the closed cup flash point of combustible liquids having flash points of between -30 and 70 °C, inclusive. However, the precision provided for this method is only valid for flash points in the range -5 and 66.5 °C.

| Industry | Application | Temperature Range | Seta Model |

|---|---|---|---|

| Adhesives and sealants | Testing esters and ketones for certification. Flammability classification for transportation regulations | Up to 150 °C | 30000-3, 35000-0, 82000-2, 82100-2 |

| Aviation and aircraft | Quality control of incoming fuels and oils. Specification conformance | 30 to 399 °C | 30000-3, 35000-0, 82000-2, 82100-2 |

| Biodiesel | Flash point testing checks that chemicals such as methanol, used in the manufacturing process are below safe levels | 130 °C | 30000-3, 35000-0, 82000-2, 82100-2 |

| Bitumen and asphalt | Used for shipping and safety regulations and to indicate the possible presence of more volatile or flammable compounds | >200 °C | 30000-3, 35000-0, 82000-2, 82100-2 |

| Chemicals | Testing solvents used in production. Safety classification for transportation regulations | Below 200 °C | 30000-3, 35000-0, 82000-2 |

| Chemical products | Flammability classification for transportation regulations | 30 to 150 °C | 35000-0, 82000-2 |

| Crude | Provides an indication about the volatility of crude oil and therefore how safely it may be extracted, transported and stored, and the potential costs involved | Below 0 °C | 82100-2 |

| Edible oils and fats | These products are used at elevated temperatures hence flash point is checked to ensure refining processes and safety limits are correctly maintained | Up to 30 °C | 30000-3, 35000-0, 82000-2, 82100-2 |

| Energy and power | Turbine and transformer oils are routinely tested for flash point to confirm product integrity from contamination that may affect performance or safety | Up to 20 °C | 30000-3, 35000-0, 82000-2, 82100-2 |

| Formulated pesticides | Research and flammability classification for transportation regulations | Up to 150 °C | 30000-3, 35000-0, 82000-2 |

| Lubricants | Quality control and research. Used oil analysis to detect evaporation/contamination by volatiles under working conditions | 30 to 399 °C | 30000-3, 35000-0 |

| Oil and gas rigs | Quality of samples. Sump contamination of pump head machinery | 30 to 399 °C | 30000-3, 35000-0, 82000-2 |

| Oil treatment/recovery | Quality control on base oils and checking contamination of used/recovered oils and fuels. Safety classification for transportation regulations | 30 to 399 °C | 30000-3, 35000-0, 82000-2 |

| Paints and varnishes | Research, quality control, and safety. Flammability classification for transportation regulations. Recommended for water-borne paints | Below 100 °C | 30000-3, 35000-0, 82000-2, 82100-2 |

| Perfumes, flavors and fragrances | Tests on solvent/water mixtures. Flammability classification for transportation regulations and safety in use | Ambient to 110 °C | 30000-3, 33200-3, 35000-0, 82000-2, 82100-2 |

| Petroleum and derivatives refining | Testing for QA/contamination where the product is pumped through a multi-product pipeline. Also used for H&S and transportation regulations | 30 to 399 °C | 30000-3, 35000-0 |

| Pharmaceuticals | Checks on manufacture stated flash points | <100 °C | 30000-3, 35000-0, 82000-2, 82100-2 |

| Printing inks | Flammability classification for transportation regulations | Below 100 °C | 30000-3, 33200-3, 35000-0, 82000-2, 82100-2 |

| Road tanker terminals/shipping terminals | Quality control of storage tanks and deliveries. Safety classification for transportation regulations | 30 to 399 °C | 30000-3, 35000-0, 82000-2 |

| Synthetic resins | Tests on solvent-resin-based base products. Quality and safety classification for transportation regulations | 15 to 150 °C | 30000-3, 35000-0, 82000-2, 82100-2 |

| Soap and synthetic detergents | Used for research and testing. Flammability classification for transportation regulations | Under 200 °C | 30000-3, 35000-0, 82000-2 |

| Transportation regulations | Flammability classification for road, rail, air, and sea | Extremely flammable <0 °C, highly flammable <21 °C, flammable <55 °C | 30000-3, 35000-0, 82000-2, 82100-2 |

| Waste disposal | Tests used to classify waste before disposal | Hexane <100 °C, Pure oil >300 °C | 30000-3, 82000-2, 82100-2 |

| Seta Part Number | Seta Model | Test Method | Temperature Range | Ramp Rate | Cup Material | Heating/Cooling Method | Size (HxWxD)/Wieght | |

|---|---|---|---|---|---|---|---|---|

| 30000-3 | Series 3 | ASTM D3278, ASTM D3828, ASTM D7236, ASTM D8174, ASTM E502 | Ambient to 300 °C | up to 6 °C/min | Aluminum | Cartridge | 195x295x140mm/3kg |

| 31000-0 | Series 3 Open Cup | ASTM D3278, ASTM D3828, ASTM D7236, ASTM D8174, ASTM E502 | Ambient to 300 °C | n/a | Aluminum | Cartridge | 260x280x260mm/5kg |

| 33200-3 | Series 3 ActiveCool | ASTM D3278, ASTM D3828, ASTM D7236, ASTM D8174, ASTM E502 | 10 to 135 °C | 2 °C/min | Aluminum | Peltier cell | 195x295x140mm/3kg |

| 33220-0 | Series 3e ActiveCool | ASTM D3278, ASTM D3828, ASTM D7236, ASTM D8174, ASTM E502 | 10 to 135 °C | 2 °C/min | Aluminum | Peltier cell | 195x295x140mm/3kg |

| 33250-3 | Series 3 ActiveCool Corrosion Resistant Cup | ASTM D3278, ASTM D3828, ASTM D7236, ASTM D8174, ASTM E502 | 10 to 135 °C | 2 °C/min | Stainless steel insert | Peltier cell | 195x295x140mm/3kg |

| 33270-0 | Series 3e ActiveCool Corrosion Resistant Cup | ASTM D3278, ASTM D3828, ASTM D7236, ASTM D8174, ASTM E502 | 10 to 135 °C | 2 °C/min | Stainless steel insert | Peltier cell | 195x295x140mm/3kg |

| 35000-0 | PM-93 Pensky-Martens | ASTM D93 | Ambient +5 to 400 °C | 5.5 °C/min | Brass | Forced air | 380.5x240x500mm/25kg |

| 82000-2 | Series 8 High Temperature | ASTM D3278, ASTM D3828, ASTM D7236, ASTM D8174, ASTM E502 | Ambient to 300 °C | 2 °C/min | Aluminum | Forced air | 300x340x380mm/8 kg |

| 82050-0 | Series 8 High Temperature Gas Ignitor | ASTM D3278, ASTM D3828, ASTM D7236, ASTM D8174, ASTM E502 | 5 to 300 °C | n/a | Aluminum | Forced air | 300x340x380mm/8 kg |

| 82100-2 | Series 8 ActiveCool | ASTM D3278, ASTM D3828, ASTM D7236, ASTM D8174, ASTM E502 | -30 to 135 °C | up to 10 °C/min | Aluminum | Peltier cell | 300x340x380mm/8 kg |

| 82110-2 | Series 8 ActiveCool Gas Ignitor | ASTM D3278, ASTM D3828, ASTM D7236, ASTM D8174, ASTM E502 | -30 to 135 °C | up to 10 °C/min | Aluminum | Peltier cell | 300x340x380mm/8 kg |

| 82150-2 | Series 8 ActiveCool Corrosion Resistant Cup | ASTM D3278, ASTM D3828, ASTM D7236, ASTM D8174, ASTM E502 | -30 to 135 °C | up to 10 °C/min | Stainless steel insert | Peltier cell | 300x340x380mm/8 kg |

| 82160-2 | Series 8 ActiveCool Corrosion Resistant and Gas Ignitor | ASTM D3278, ASTM D3828, ASTM D7236, ASTM D8174, ASTM E502 | -30 to 135 °C | up to 10 °C/min | Stainless steel insert | Peltier cell | 300x340x380mm/8 kg |

| 34300-2 | Seta C92 Automated Cleveland Open Cup Flash and Fire Point | ASTM D92, ASTM D8254, IP 36, ISO 2592, DIN 51 376, NF T60-118, JIS K 2265-4, AASHTO T48 | Ambient to 400 °C | n/a | Brass | Hotplate/Fan assisted or Forced air | 330 x 470 x 420 mm/12 kg |

| 13220-2 | Seta Semi-Automatic Tag Flash Point Tester (open cup model available for methods ASTM D1310 & ASTM D3143) | ASTM D56, ASTM D3934, ASTM E502 | Ambient to 93 °C | Variable, manually controlled | Brass | Electrical heater | 33 x 31 x 29 cm/5 kg |

The test method chosen must follow the stated requirements, however, if this requirement is flexible then the choice may be biased towards safety, cost, speed of the test, and even instrument availability. Below are important factors to consider before making your choice.

Safety Features

The need to heat and ignite potentially flammable liquids in a laboratory is naturally of concern and in many instances, the use of a naked flame is prohibited. ASTM D3828 Small Scale flash point tests reduce the risk by using a small sample of just 2 or 4 ml.

Most test methods now permit the use of an electric ignition source as an alternative to the traditionally used gas flame with some flash point testers providing users with a choice of either Ease of use.

Fire Extinguishing Systems

A fire extinguishing system is now mandatory for all ASTM D93 Pensky-Martens flash point testing apparatus manufactured after 2016. The Seta PM-93 now provides an automatic fire extinguisher system which, separately from temperature sensors used to monitor the sample and control instrument performance, will automatically and immediately activate an integral extinguisher in the event of flame or fire being detected around the test cup. Additional safety features include PRT checks, safety dip before starting, over-temperature cut-out, gas flame relight, gas shut off, and emergency stop.

Ease of Use

Automated Pensky-Martens flash point testers have been designed to provide rapid testing of samples with minimal operator input. The Seta PM-93 allows unsupervised operation which heats the sample at the temperature rate prescribed in the test method whilst also applying ignition and checking for flash automatically.

Setaflash Small Scale point testers operate using gas or electric ignition and are very easy and reliable to use. The simple flash/no flash test requires minimum analytical experience to achieve a reliable result. Small volumes allow rapid and very safe sample handling and Series 3 models weighing just 3 kg, can be powered by a battery and are easily carried to the sample.