Oxidation Bath with Oxflo Controller – 16900-7

The Seta Oxidation Bath is used for quantitative analysis of the tendency of oils and fuels to form sludge, acids, and deposits when exposed to oxygen in the presence of metallic catalysts over extended periods.

Methods: ASTM D943, ASTM D2274, ASTM D4310, ASTM D7462, IP 157, IP 388, BS EN ISO 12205 & BS 2000-388 & ISO 12205, DIN 51 587, ISO 4263

Features

- Ambient +5 °C to 120 °C temperature range

- 6 position oil bath

- Reliable digital thermostir unit

- Seta Oxflo Controller and flowmeters included

- Low liquid protection

- Over-temperature cut out

The 35-liter oil bath can accept up to six sets of glassware. The stirred oil is maintained to within ±0.1 °C at 95 °C by an integral thermostir unit, that has been designed for continuous use over extended periods, incorporating a stirrer motor well recognized for longevity. The temperature measurement system uses a PT100 probe to ensure long term temperature stability without routine maintenance or re-calibration.

The separate Oxflo control unit includes a gas inlet pressure regulator, pressure gauge and six precision flowmeters calibrated for oxygen at 3 liters/hour, 21 °C and 0.4 bar pressure.

Safety features include low-level liquid protection and over-temperature cut-outs.

Note: Glassware and catalysts must be ordered separately.

| TEMPERATURE RANGE | Ambient +5 °C to 150 °C |

|---|---|

| STABILITY | ±0.05 °C |

| BATH TYPE | Oil-filled |

| BATH CAPACITY | 35 liters |

| POWER | 1.5 kW |

| VOLTAGE | 110/120 V, 50/60 Hz 220/240 V, 50/60 Hz |

| SIZE (HXWXD) | Bath: 64 x 36 x 33 cm Oxflo Control Unit: 44 x 35 x 26 cm |

| WEIGHT | Bath: 15 kg Oxflo Control Unit: 11 kg |

| CCCN CODE | Tariff 90318080 |

Accessories, Spares, Calibration, and Training

-

Thermometer ASTMS22C: Low Haz with Certificate of Conformity – ASTMS22CX

-

Bath Oil 80 – 120 °C (20 liters) – 94635-0

-

Silicone Bath Oil 120 – 150 °C (20 liters) – 94632-0

-

Silicon Carbide Paper P100 FEPA Grade (Pack of 50) – 11470-0

-

Pre-Formed Copper and Steel Catalyst Coil (pack of 6) – 16921-0

-

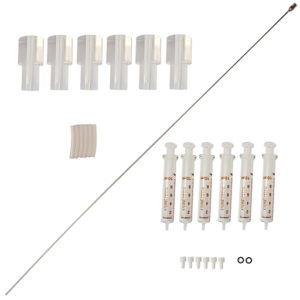

Set Glassware ASTM D943, ASTM D4310, ISO 4263, IP 157 (6 cells) – 16911-0

-

Set Glassware ASTM D2274, D7462, ISO 12205, IP 388 (6 cells) – 16910-0

-

ASTM D943 & D4310 Accessory Pack – 16950-0

-

Sample Filtering Kit for ASTM D2274 – 16914-0

-

Thermometer for ASTM D943 & D4310 Oxidation Cell: Low Haz – 16980-2

-

Series 520 PT Analytical and Precision Balances

-

Air Expert Ovens