Lubricant Testing Solutions

Flash Point

Flash point is a key property for lubricating oils and is included in many specifications. All petroleum products will ignite if raised to a sufficiently high temperature. It is essential that lubricating oils have flash and fire points that are well above their expected operating temperatures. Flash point is also commonly used to determine whether lubricating oils have been contaminated with volatile materials and is a standard test when assessing used lubricants.

PM-93 Pensky-Martens

ASTM D93, IP 34, ISO 2719

The Seta PM-93 is a fully automated Pensky-Martens Closed Cup Flash Point Tester that combines strict method conformance with state-of-the-art control technology and safety systems to provide the next generation of automated precision flash point instruments.

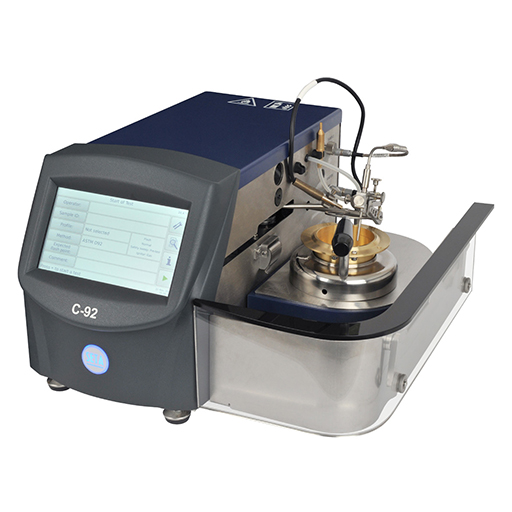

Cleveland

ASTM D92, ASTM D8254, IP 36, ISO 2592, DIN 51 376, NF T60-118, JIS K 2265-4, AASHTO T48

These test methods describe the determination of the flash point and fire point of petroleum products by a manual Cleveland open cup apparatus or an automated Cleveland open cup apparatus. It is applicable to all petroleum products with flash points above 79 °C and below 400 °C except fuel oils.

Setaflash Small Scale

ASTM D3278, ASTM D3828, ASTM D7236, ASTM D8174; ASTM E502, IP 523, IP 524, IP 534, ISO 3679,

ISO 3680

Flash point, as part of an oil condition monitoring program, can reliably identify degradation and contamination of the oils from fuel dilution. It can complement other tests, such as viscosity measurement, and can be used to confirm whether a low viscosity result is due to improper blending, lubricant breakdown, or fuel dilution. Fuel contamination of under 1% can be detected with small-scale instruments.

Many labs utilize the small scale flash point, which typically provides a result in under two minutes as opposed to 30 minutes or longer with Cleveland or Pensky-Martens testers.

Viscosity

Viscosity is a critical property that determines the ability of the lubricating oil to form a film that protects moving machinery components from wear during operation. Kinematic viscosity forms an integral part of lubricating oil specifications.

Viscol-20AS Dual-Bath Kinematic Viscometer

ASTM D445, ASTM D446, ISO 3104, ISO 3105, IP 71

Viscol-20AS is a fully automated dual-bath kinematic viscometer according to ASTM D445/D446 for kinematic viscosity measurements of all Newtonian type fluids. The unit is equipped with two separate baths for measurements at 40C and 100C simultaneously, and each bath has a 23-position autosampler unit.

All Viscol units are equipped with the latest temperature control, wide-range capillary, precise time detection, and washing features to ensure consistent and precise results for each measurement.

RUV-2 Automated Kinematic Viscometer

The PSL Rheotek RUV is suitable for determining the kinematic viscosity of a wide range of petroleum liquids, including jet fuel, diesel, residual fuels, base oils, and formulated oils, including black oils.

Designed with product specification testing in mind, the RUV uses a standard ASTM Ubbelohde Viscometer tube. All measurements are fully compliant with ASTM D445. For each result reported, the unit requires duplicate flow times within the determinability required for the type of sample in the tube. Robust performance is the backbone of this refinery laboratory workhorse.

The PSL Rheotek Kinematic Viscometer consists of a single or dual analyzer module, inclusive of control system, viscometer bath, and up to 4 universal measuring positions.

KV-2 Low Temperature Viscometer Bath

ASTM D445, ASTM D446, IP 71, BS 188, BS 2000-71-2 & ISO 3105, BS EN ISO 3104 & BS 2000-71.1 & ISO 3104

The Seta KV-2 is a two place low temperature viscosity bath designed to achieve ultra-high stability in the temperature range of +20 °C to -40 °C. The bath offers high stability of, and ±0.01 at -20°C. Temperature is measured by a PT100 probe, a twin display shows the current and set temperature.

Particle Counting

The understanding of particle contamination in lubricating and hydraulic oils is the single most important parameter when evaluating the cleanliness of new and used lubricating and hydraulic oils. Laser particle counting offers a quick and quantitative way of evaluating the particulate contamination or cleanliness of oil, allowing an operator to determine whether the oil is suitable for operation. Particle counting methods are written into many specifications, and the instruments report particle count and size distribution in industry standard formats such as ISO 4406 and NAS 1638.

AvCount3 Particle Counter

ASTM D975, ASTM D7467, ASTM D7619, ASTM D7647, IP 565, IP 630, DEF STAN 91-091, DEF STAN 91-86, GOST 17216, ISO 4406, ISO 60970, JIS B 9932:2012, JIS B 9933:2021, JIS B 9934:2012, NAS 1638

The AvCount3 is a compact bench-top automatic particle counter, used to measure the size and distribution of particles and water droplets in light and middle distillate fuels, including aviation fuel and kerosine, biodiesel, low viscosity oils, and hydraulic oils.

Featuring a simple user interface with a touchscreen display, the fully-automated test means extensive operator training is not required before using the instrument. The simplicity of test setup and automation gives operators the time to work on something else, helping to reduce labor costs.

4-Ball and Shear Stability

Shear stability measures a lubricant’s resistance to viscosity loss when passed through narrow passageways such as bearings or gears. A common test for this property is the Taper Roller Bearing Rig (KRL) test CEC-L-45-99.

Seta-Shell Four Ball Lubricant Tester

ASTM D2266, ASTM D2596, ASTM D2783, ASTM D4172, IP 239, BS EN ISO 20623, BS ISO 26422, CEC L-45-T-93, DIN 51 350

The Seta-Shell Four Ball Lubricant Tester (manual load) determines friction and wear properties of extreme pressure oils and greases. Used in tribology research laboratories and in the routine quality control of finished lubrication products.

Seta High-Temperature Roll Stability Tester

ASTM D1831, ASTM D8022

The Seta Roll Stability Tester is used for shear stability testing lubricant greases by simulating the effect of squeezing grease between the rollers and the outer face of a roller bearing.

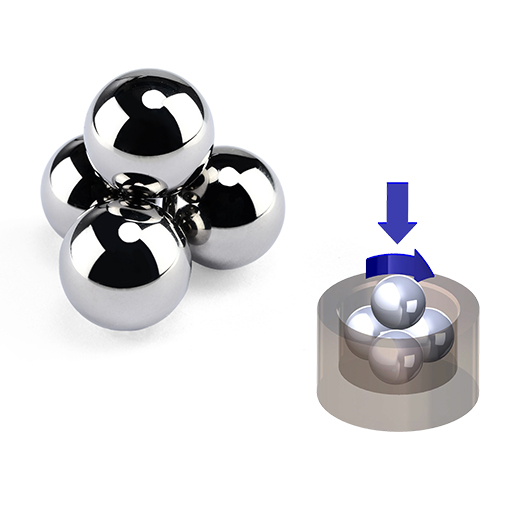

4-Ball Specimens

ASTM D2622, ASTM D2596, ASTM D2783, ASTM D4172

FenixES Four Ball Specimens are sold as a pack of 400 balls. The ball specimen is a 12.7 mm diameter. The specimens are manufactured to comply with ASTM D2266, D2596, D2783, and D4172 test methods. You can contact us for more detailed information.

Foaming, Air Release, Water Seperability Characteristics

Emulsion, defined as a dispersion of one liquid into another, a mixture of two liquids and not a solution with one liquid devolved into the other.

A foam is an emulsion in which the dispersed phase is a gas rather than a liquid. The foaming and emulsion characteristics of hydraulic fluid are important to system performance because the fluid can pick up and contain contaminants that can affect its properties and functional ability.

Lubricants and oils containing excess amounts of entrained air can lead to serious disruptions of equipment in operation, increased oxidation tendency and shortened lubricating efficiency.

SetaFoam Dual Twin Foam Test Baths

ASTM D892, IP 146, ISO 6247

These pair of highly transparent water baths are for detecting undesirable foaming characteristics in lubricating oils, which could cause inadequate lubrication, overflow, and cavitation.

The instrument comprises a high temperature (normally 93.5 °C) and a low temperature (normally 24 °C) bath, each with the capacity to hold four 1000 ml graduated glass cylinders.

Air Release Value System

ASTM D3427, IP 313, BS 2000-313, ISO 9120

The Seta Air Release Value System is designed to determine the air release properties of hydrocarbon-based oils in accordance with ASTM, IP, and other methods.

The system comprises a benchtop instrument with integrated density balance, heater, temperature control system, pressure regulation, and microprocessor-based control system.

Herschel Emulsifier

ASTM D1401, IP 412, ISO 6614

The Herschel Emulsifier is a compact and efficient benchtop instrument designed to measure the ability of petroleum oils and synthetic fluids to separate from water.

The instrument incorporates 4 test stirrers, with independent control and motorized raising and lowering. Samples can be tested simultaneously or individually to suit laboratory requirements.

Oxidation Characteristics

Oxidation stability provides an indication of the service life of the oil. ASTM D943 covers the Oxidation Characteristics of Inhibited mineral oils. ASTM D4310 covers the sludging and corrosion tendencies of the oil in the presence of a metal catalyst.

Oxidation Bath with Oxflo Controller

ASTM D943, ASTM D2274, ASTM D4310, ASTM D7462, IP 157, IP 388, BS EN ISO 12205 & BS 2000-388 & ISO 12205, DIN 51 587, ISO 4263

The Seta Oxidation Bath is used for quantitative analysis of the tendency of oils and fuels to form sludge, acids, and deposits when exposed to oxygen in the presence of metallic catalysts over extended periods.

Corrosiveness to Copper

Corrosion testing was introduced to automotive lubricating oil specifications in response to concerns over corrosion damage to engine components. The ASTM D130 test utilizes Copper tokens that are exposed to the sample in the presence of heat, and the resulting change in token color is compared to an ASTM color standard.

Seta Silver and Copper Corrosion Bath

ASTM D130, ASTM D4048, ASTM D7667, ASTM D7671, IP 112, IP 154, IP 611, BS EN ISO 2160 & BS 2000-154 & ISO 2160, DIN EN ISO 2160, ISO 2160

The Seta Silver and Copper Corrosion Bath is a bench top, stainless steel water or oil bath. Digitally controlled to ±0.1 °C over a temperature range of ambient +5 °C to 150 °C, the bath is used to determine the corrosive effects of fuels, lubricants, and other hydrocarbon products on copper and silver.

Rust Preventing Characteristics

A test that is included in most lubricating and hydraulic oil specifications and frequently used as part of an oil condition monitoring program. In use water can become entrained in the oil and the test provides a guide on how well the oil will protect metal surfaces from rusting due to the water content, it also indicates whether rust inhibitors are required.

Seta Rust Prevention Test Bath

ASTM D665, ASTM D3603, ASTM D5534, IP 135, ISO 7120, NACE TM0172

The bath allows determination of the ability of steam turbine oils to prevent rusting of ferrous components and to test the corrosive properties of cargoes in petroleum product pipelines.

The 31-litre capacity oil bath has a temperature range of ambient +5 °C to 120 °C and is controlled by a remote digital thermostir unit calibrated at 60 ° C ±0.1 °C. The top panel of the bath accepts up to seven test beakers. Each beaker is stirred at 1000 ±50 rpm by a quick release paddle stirrer.

Carbon Residue

Typically called up in base oil specifications, this test provides an indication of carbon deposits that may remain after an oil’s exposure to high temperatures. Two tests cover this property: ASTM D4530 – Micro carbon residue and ASTM D189 Conradson Carbon residue. The tests require different volumes of samples; ASTM D4530 is accepted as the referee test. A third test, ASTM D524 Ramsbottom Carbon residue, is also sometimes used and can be correlated to D4530 and D189.

Micro Carbon Residue Tester

ASTM D189, ASTM D4530, IP 13, IP 398, BS EN ISO 10370 & BS 2000-398, ISO 6615, ISO 10370

The Micro Carbon Residue Tester is an automatic airtight furnace that is pre-programmed to run tests to determine the Micro (Conradson) Carbon residue of petroleum products.

The digitally controlled furnace has a temperature range of ambient to 500 °C. Temperature, flow, and pressure values are automatically controlled, and values are displayed on the control panel. The test cycle includes an audible ‘end of test’ alarm.